Arduino was designed to make embedded systems more familiar. Before Arduino, microcontrollers were not easy to deal with. Arduino with its open-source platform reduced the gap between microcontrollers and programmers. On the other hand, PLC also known as Programmable Logic Controller is a robust computer control system that automates industrial tasks, machine function and even automates the whole industrial production line. PLC is like a CPU designed to work under harsh industrial conditions.

Is Arduino a PLC

Yes, one can say that Arduino is a PLC because both Arduino and PLC use a controller to take inputs and execute them accordingly. PLC is a microcontroller designed for industrial applications while Arduino is a controller board that targets beginners and small-scale applications. Only difference which exists between them is that Arduino uses conventional programming language like C++ to process data while PLC programming is built upon Ladder-logic programming.

One of the main differences between Arduino and PLC is that both are manufactured for two different environments. PLC systems are very expensive to buy and repair, also PLC required specific skill from software designers to extract high potential using PLC controllers. Arduino due to its popularity is a kind of universal programmable controller that has its separate and easy to use programming platform IDE.

Can Arduino Be Used As PLC

Yes, Arduino can be used as a PLC. Working of Arduino is somehow like a PLC controller but due to the limited number of I/O pins Arduino cannot completely replace PLC in industries. As the technology grows multiple platforms emerge like controllino and automationdirect that design Arduino based industrial PLC controllers which are cheaper but work the same like industrial PLCs.

List of Arduino Based PLC

-

- Industrial Shields Arduino PLCs

- Controllino Arduino PLCs

Industrial Shields Arduino PLCs

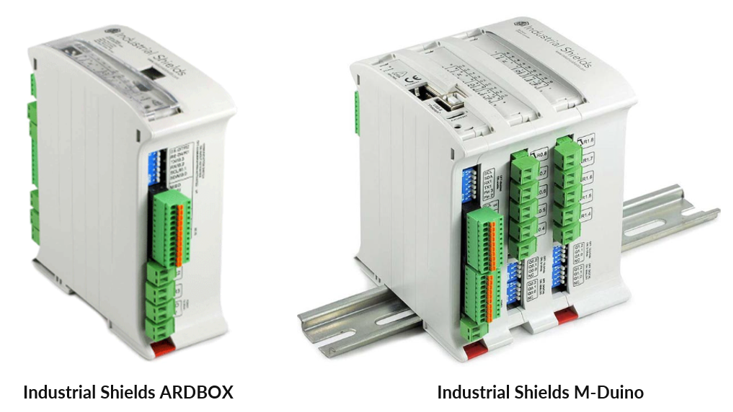

Industrial Shields is a leading manufacturer of Arduino based PLC shields. Multiple shields are designed by this group among all ARDBOX and M-Duino are the most popular ones.

The ARDBOX is based upon Arduino Leonardo and is designed for medium scale applications. M-Duino is designed using Arduino Mega board. Most of the technical specifications of the M-Duino are the same as Arduino Mega board.

Controllino Arduino PLCs

Controllino is another Arduino based platform very famous for designing PLCs using Arduino boards. Controllino combines the open-source Arduino platform with industrial base PLCs. Some of the most used Arduino PLCs designed by this company are Controllino Mega and Controllino Mini. Controllino Mega is designed using the ATmega2560 controller normally used in Arduino Mega boards. Controllino Mini is based upon Arduino UNO board and uses the same chip as Arduino UNO.

Brief comparison of all these boards is shown in the table below:

| Specifications | ARDBOX | M-Duino | Controllino Mini | Controllino Mega |

| Input Voltage | 12V or 24V | 12V or 24V | 12V or 24V | 12V or 24V |

| Microcontroller | ATmega32u4 | ATmega2560 | ATmega328p | ATmega2560 |

| Max Current | 1.5A | 1.5A | 6A max relay output current | 6A max relay output current |

| Clock Speed | 16MHz | 16MHz | 16MHz | 16MHz |

| Programming Language | Arduino IDE | Arduino IDE | Arduino IDE | Arduino IDE |

| Flash Memory | 32KB | 32KB | 32KB | 256KB |

| SRAM | 2.5KB | 2KB | 2KB | 8KB |

| EEPROM | 1KB | 1KB | 1KB | 4KB |

| Communication | I2C-USB-SPI-TTL-RS232-RS485 | I2C1-USB-SPI-Ethernet-RS232-RS485-Tx, Rx | I2C1-USB-SPI-TTL | I2C1-USB-SPI-Ethernet-TTL-RS485 |

| Total Input Points | 10 | 13,26,36 | 8 | 21 |

| Total Output Points | 10 | 8,6,22 | 8 | 24 |

Arduino and PLC – Comparison

One cannot say that Arduino is better than PLC or vice versa. Comparing Arduino and PLC is not an easy task and now with Arduino based PLCs it has become a more arduous task to do. Both have advantages and disadvantages depending upon their environment. Here are some points that show a brief comparison between them:

-

- Arduino stores only machine code so it makes it impossible to download and troubleshoot the code while PLC stores its code with comments, variable name, instructions and using PLC we can even download our project code and modify it easily.

- With PLCs it’s possible to upload new code without stopping the whole production process while Arduino does not allow making real time One must shut down the system completely to make changes or upload a new code.

- Arduino does not have a real time view for data monitoring while PLC allows users to analyze real time data and monitor the ladder code.

- In Arduino I/O pins need to be declared before we even start our project but with PLCs most of the pins all already mapped that makes it easy to program

- With PLCs we have CPU, I/O and communication watchdogs that prevent PLC from getting stuck into a loop while to do this in Arduino we need to program it before we use it with our project.

Advantages of Arduino PLC

-

- Available at low cost

- Can be easily programmed using Arduino IDE

- Adjustments can be made easily

- Easy to replace

- Low repairing cost

Disadvantages of Arduino PLC

-

- Limited choices are available

- Not compatible with high scale industrial applications

- Need frequent maintenance compared to conventional PLCs

- Limited I/O pins

- Real time changes cannot be made

Conclusion

Arduino is one of the favorite platforms for people that design electronic projects. With advancement in Arduino boards, they make their way to industrial automations. For a long time, PLCs were the leading controller in the industrial world but now Arduino based PLCs have made their place in industries due to their much lower cost than conventional PLCs.