Linear Variable Differential Transformers (LVDT)

The LVDT is a type of electromechanical device that is utilized in both electrical and mechanical processes. The position sensors of LVDT are used to measure very small movements of objects to very large movements of 30 inches. The reason to name it a differential device is because the output through the secondary is differential.

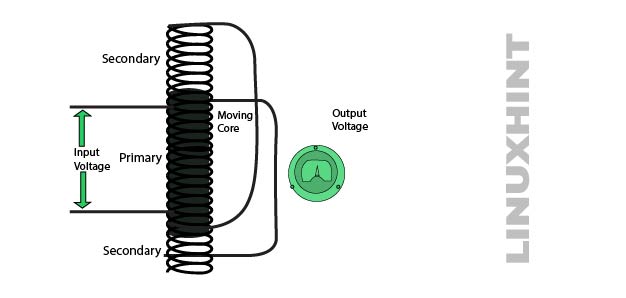

The above-given figure is the structure of LVDT. The LVDT structure is made up of one primary and two secondary windings. AC voltage is applied across the primary winding which results in the flux in the air gap which results in the induced voltage in the secondary windings. The difference between two secondary windings determines the output voltage.

Operation and Working Principle

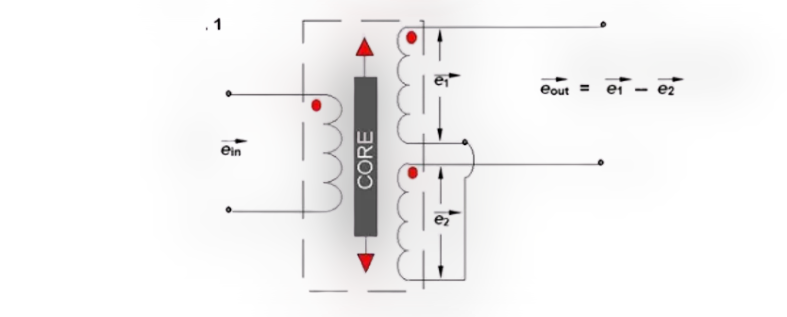

The AC voltage is applied across the primary winding which induces the voltage in the secondary windings, the voltage in S1 windings is given by e1 and the voltage in S2 is given by e2. Below, the given figure shows the AC input in voltage and the resultant output out voltage.

Three cases arise based on core and windings:

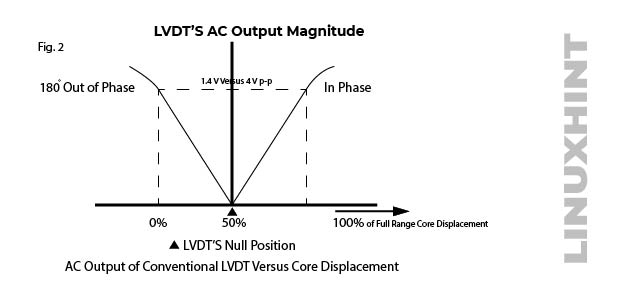

Case 1: null position of core

The null position of the core means the induced voltage in both the secondary windings is the same. Position means zero displacement, so the output voltage is the difference of both secondary windings, which is zero:

Case 2: up of null movement

In this case, the core is moved up from its reference position which results in more voltage in secondary winding S1 as compared to the secondary winding S2. As the output voltage is the difference between S1 and S2 voltage positive voltage will be produced in this case:

Case 3: down of null movement

In this case, the core is moved down from its reference position which results in more voltage in secondary winding S2 as compared to the secondary winding S1. As the output voltage is the difference between S1 and S2 voltage negative voltage will be produced in this case:

The above-given figure is the structural diagram of LVDT in which the core and all three windings are clearly shown. There are many advantages of LVDT such as it measures very accurately. There is no fraction in the movement of the core. It directly converts linear displacement into electrical signals.

Conclusion

The most crucial tool utilized in industries is the linear variable differential transformer. It is used to convert linear displacement into electrical signals. Different types of cases occur according to the movement of the core.