Outline:

How to Check a Motor Capacitor

How to Check a Motor Capacitor

Capacitors usually tend to last a longer time due to their internal composition, but their life span can be affected if subjected to higher voltages or any surges. In motors as mentioned above, there are two capacitors spending in the type of the motor and if any of the capacitors is bad then it will affect the functioning of the motor. So, to check the capacitor of a motor there are various ways:

Check the Capacitance Value

The first thing to do for checking the capacitor is to find its actual capacitance value because sometimes the capacitor does not provide enough capacitance, resulting in motor failure. So, to get the actual value of capacitance you need to have a multimeter with the option of measuring capacitance. Turn on the meter move the dial to the capacitance symbol and connect the red lead of the multimeter to the positive terminal and vice versa:

Now see the value of capacitance displayed on the meter and compare it with the printed range for the value of capacitance on the capacitor. If the value falls under this range, then if means that the capacitor is in good condition, and if not then it needs to be replaced.

Check Resistance

To check if the capacitor is blown or short-circuited the best method for it is to check its resistance and if it shows an infinite resistance then it means that the capacitor is still good. So, to check the resistance you need either a digital or analog multimeter, move the dial to the resistance symbol and connect the probes of the multimeter with the capacitor:

At first, the meter will display the resistance value rising gradually and then suddenly it will go to zero however if you are using a meter with auto range then it will keep on increasing. Now change the direction of the probes to see the resistance when the capacitor discharges:

If for both the charging and discharging the resistance is increasing, then it means that the capacitor is not blown or short-circuited. Also, note that in the case of an analog meter, it will show only deflection, which means the capacitor is not blown.

Check the Capacitor Voltage

Sometimes the capacitor is not holding the charge or there is any issue with it while charging, so in that case charge the capacitor and check its voltage via multimeter. Here are some steps for this method:

Step 1: Discharge the Capacitor Completely

Usually, the capacitors are not fully discharged, so to charge a capacitor for testing purposes it is necessary to have it completely discharged. So, to discharge a capacitor, simply place a screwdriver between its positive and negative terminals:

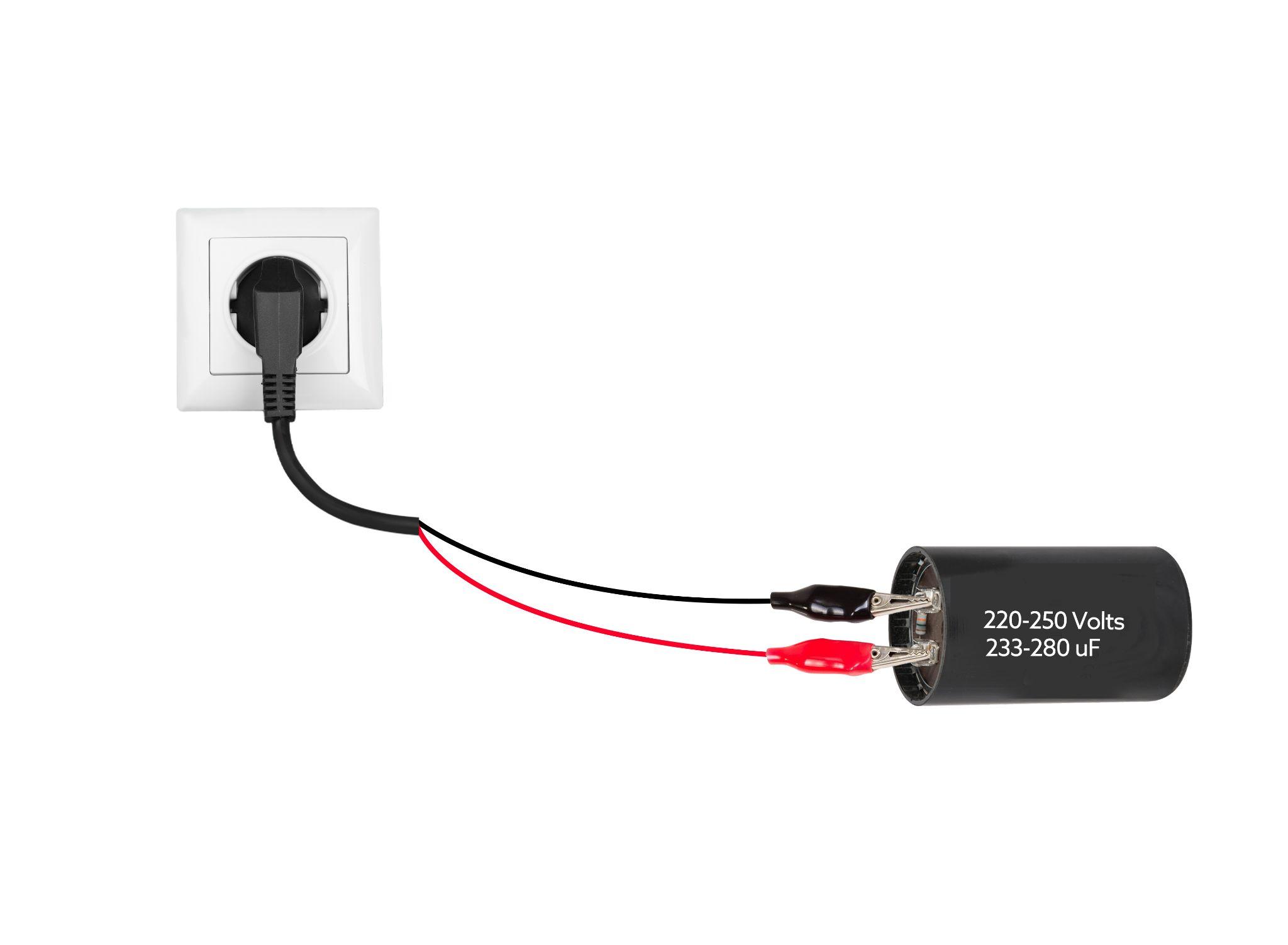

Step 2: Charge the Capacitor

Since the motor runs on alternating current, it usually has a non-polarized capacitor, so connect the capacitor with an AC supply for just one second:

Step 3: Measure the Voltage

Now to see if the capacitor is changed just place the screwdriver between the terminals of the capacitor and if a spark occurs it means that the capacitor is good:

On the other hand, use the multimeter to check the voltage on the capacitor, just set the dial to the voltage and connect the multimeter probes to the capacitor.

If the voltage is somewhat near the voltage of the power supply, then it means the capacitor is in good condition, and if not then it needs to be replaced.

Note: Before trying all the above methods, it is important to fully discharge the capacitor using the screwdriver. Moreover, care should be taken while charging and discharging the capacitor. Also, the methods for checking the start and run capacitor are the same.

Conclusion

Capacitors are passive devices that store electrical charge between their electrodes, and this energy can be used for a number of different applications. One is its use in motors, there are two types of capacitors in motors one is the start capacitor, and the other is the run capacitor. Some motors have both capacitors, while some have only start capacitors.

To check a motor capacitor, disconnect it from the motor and find its actual capacitance value, check its resistance, or measure its voltage by charging it. If in any of the methods the capacitor doesn’t perform well, it means that it is worn out.