Outline

What is a Ceramic Disc Capacitor?

Construction and working of Ceramic Disc Capacitor

Ceramic Capacitor Classes

Reading Ceramic Capacitor Values

Ceramic Capacitors as Coupling Capacitors

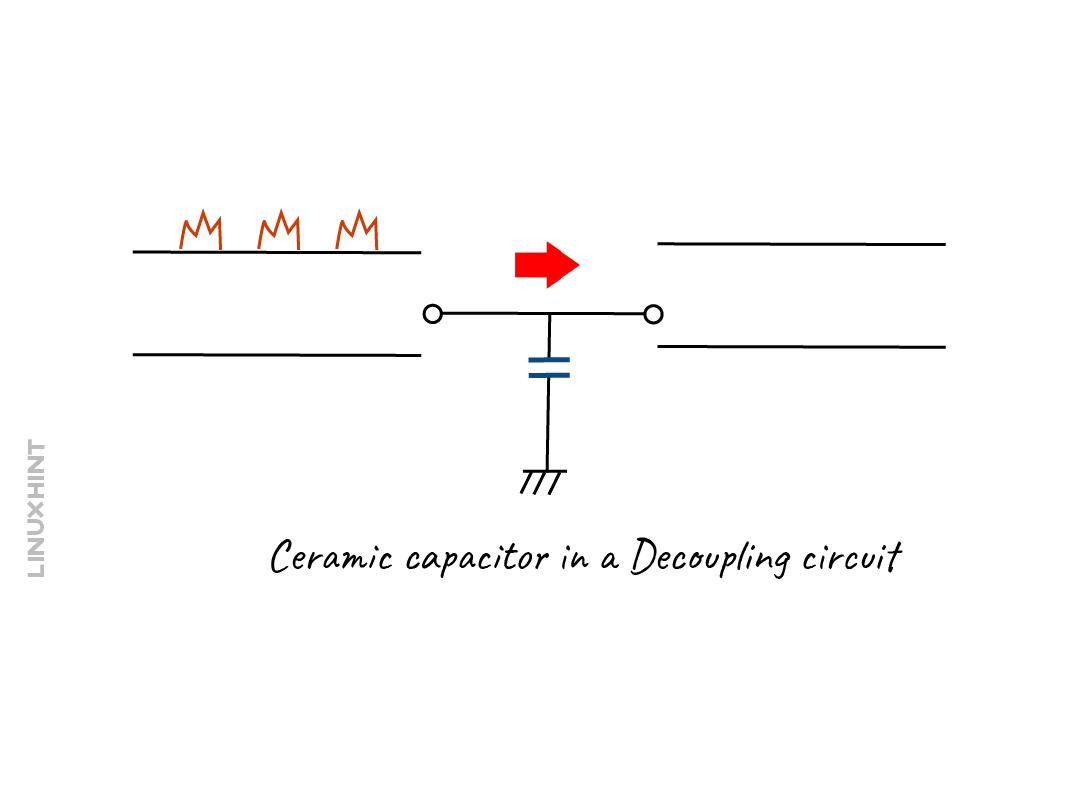

Ceramic Capacitors as Decoupling Capacitors

Conclusion

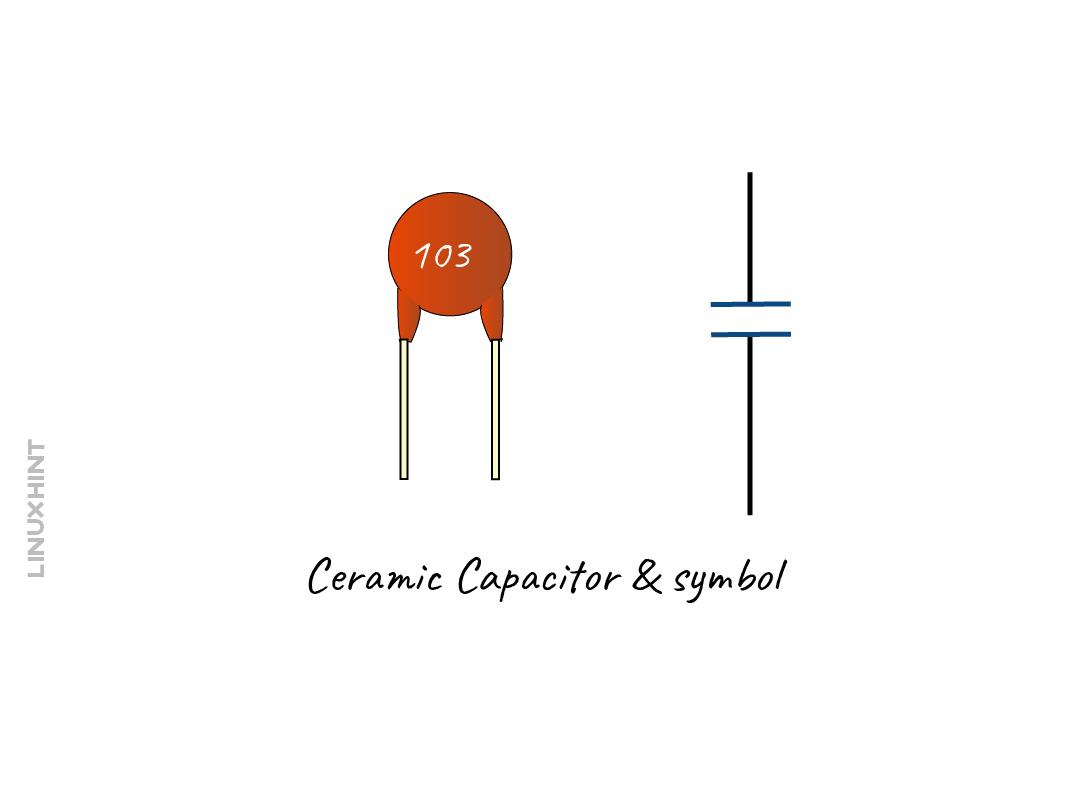

What is a Ceramic Disc Capacitor?

Ceramic capacitor is the most widely used capacitor in electric circuits as it is reliable and not very expensive. These capacitors have ceramic material between their plates as an insulating material, as this material is known for its insulating properties. The ceramic capacitor is further divided into two types, one of which is the ceramic disc capacitor.

The ceramic capacitors have a low capacitance that ranges between 1nf to 1µf, and thus they have low rated voltage when compared with the electrolytic capacitors. The capacitors are used for DC circuits, so they come under the category of polarized capacitors.

Construction and working of Ceramic Disc Capacitor

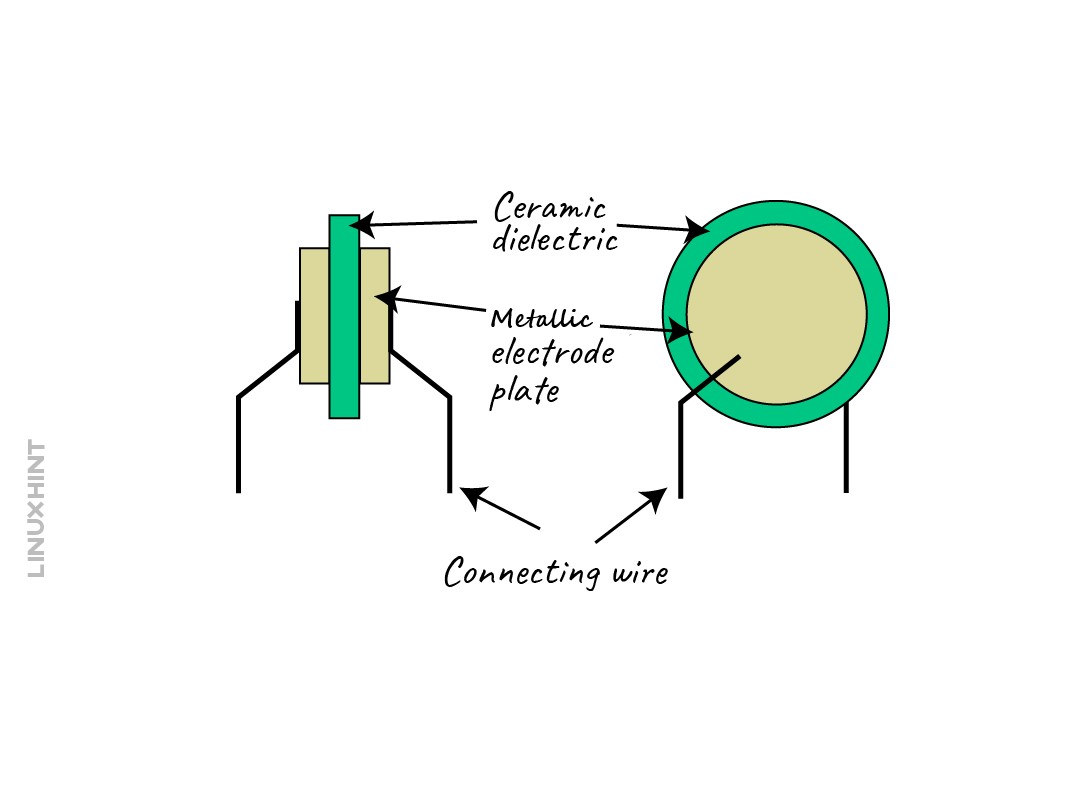

The ceramic disc capacitor is a disc-shaped capacitor having disc-shaped electrodes with a disc-shaped ceramic material between them. The outer of the capacitor is layered with a protective coating and silver contacts are connected with the electrodes of the capacitor:

Since the capacitance depends on the area of plates and the permittivity of the insulating material, based on the material of the dielectric, the ceramic disc capacitor is divided into three different classes. Since these are polarized capacitors, they will only work with the DC supply, these capacitors work in the same way just like a general capacitor.

However, the capacitor blocks the flow of the current when fully charged, and this is because it reaches the same potential level as that of the supply voltage. This behavior makes these capacitors suitable for filtering high or low frequencies, bypassing any signals, converting from AC to DC, and more.

Ceramic Capacitor Classes

Based on dielectric materials, these ceramic capacitors can be classified into different classes, as the permittivity of the insulating material greatly affects the capacitance and the behavior of the capacitor. The ceramic materials that are used for dielectric in the disc capacitors include paraelectric or ferroelectric ceramics. However, using a paraelectric mixture based on titanium dioxide as a dielectric increases the stability of the capacitor and lowers the losses at higher frequencies. These mixtures have provided lower capacitance and tend to have lower permittivity.

On the other hand, the mixture of ferroelectric ceramic materials like barium nitrate along with the suitable oxides have comparatively higher permittivity, resulting in higher capacitance. However, the changes in the temperatures result in non-linear behavior of the capacitor, and not only that the losses at the higher frequencies are also high.

Due to such characteristics of the dielectrics, it is needed that based on the properties they should be grouped. So, there are two standards for grouping, one is the International Electrotechnical Commission (IEC) and the other one is the Electronic Industry Alliance (EIA). Both of these have divided the ceramic capacitors into three different classes.

Class 1 Ceramic Disc Capacitor

Class 1 includes ceramic capacitors that provide a stable voltage, compensate for any changes in the temperature, and provide a stable frequency in most cases. The capacitors for this class usually have losses due to high frequencies and are used in applications where a stable temperature coefficient is required. For instance, using a ceramic disc capacitor in a circuit to compensate for the fluctuations in the temperature.

The base material used for ceramic capacitors in class 1 is titanium dioxide which is mixed with some additives like magnesium, zinc, cobalt, zirconium, strontium, and niobium. These materials make the behavior of the capacitor linear and are added in a specific quantity to adjust their temperature characteristic. Here is the table that shows the temperature coefficients of different materials that are used in the class 1 ceramic disc capacitors:

| Material Formula | Temperature Coefficient | Relative Permittivity |

|---|---|---|

| MgTa2O6 | 18 | 28 |

| ZnTa2O6 | 9 | 38 |

| (ZnMg)TiO3 | 5 | 32 |

| Ba2Ti9O20 | 2 | 40 |

| (ZrSn)TiO4 | 0 | 37 |

| ZnNb2O6 | -56 | 25 |

| MgNb2O6 | -70 | 21 |

Class 1 capacitors have a dissipation factor of only 0.15 percent due to which they exhibit quite fewer losses, and the temperature coefficient is quite stable with the variation in the temperature range. Moreover, the capacitance of these capacitors merely depends on the applied voltage.

Now as described above there are two sets of standards that define the classes of ceramic capacitors. So, according to the Electronic Industry Alliance (EIA), there are three character codes for class 1 that illustrate the temperature coefficient. The first one displays the significant figure for the variation in the capacitor capacitance due to the temperature.

The second character gives information about the multiplier for the coefficient of temperature, and the third one displays information about the tolerance in parts per million per kelvin (ppm/k). Here is the table of the temperature coefficient for the ceramic disc capacitors according to the EIA standard:

| Mantissa

(ppm/°C) |

Multiplier for Temperature Coefficient | Tolerance for Temperature Coefficient

(ppm/°C) |

|||

|---|---|---|---|---|---|

| Code | Value | Code | Value | Code | Value |

| C | 0.0 | 0 | -10° | G | ±30 |

| B | 0.3 | 1 | -101 | H | ±60 |

| L | 0.8 | 2 | -102 | J | ±120 |

| A | 0.9 | 3 | -103 | K | ±250 |

| M | 1.0 | 4 | +100 | L | ±500 |

| P | 1.5 | 5 | Invalid | M | ±1000 |

| R | 2.2 | 6 | +101 | N | ±2500 |

| S | 3.3 | 7 | +102 | ||

| T | 4.7 | 8 | +103 | ||

| U | 5.6 | ||||

| V | 7.5 | ||||

Nowhere in the table if the code is C0G then it means that the capacitor has zero temperature coefficient which means that it has a tolerance value of ±30. It is to be noted that the temperature range at which this temperature coefficient and tolerance are based is not the actual operating temperature of the ceramic capacitor. Now for the other standard the codes for the temperature coefficient according to the IEC are given in the table below:

| Ceramic Codes | Temperature

coefficient α 10−6 /K |

Tolerance

10−6 /K |

Sub-class | IEC/ EN Letter

Codes |

EIA standard

Codes |

|---|---|---|---|---|---|

| N1500 | -1500 | ±250 | 1F | VK | P3K |

| N1000 | -1000 | ±250 | 1F | QK | Q3K |

| N750 | -750 | ±120 | 1B | UJ | U2J |

| N470 | -470 | ±60 | 1B | TH | T2H |

| N330 | -330 | ±60 | 1B | SH | S2H |

| N220 | -220 | ±60 | 1B | RH | R2H |

| N150 | -150 | ±30 | 1B | PH | P2H |

| N75 | -75 | ±30 | 1B | LG | L2G |

| N33 | -33 | ±30 | 1B | HG | H2G |

| NP0 | 0 | ±30 | 1B | CG | C0G |

| P100 | 100 | ±30 | 1B | AG | M7G |

So now here the NP0 code in the IEC standard is equal to the G0G code of the EIA standard both have zero drift and tolerance is around the value of ±30. So, the same is the case for the N1500 and P3K codes for both the two standards.

Class 2 Ceramic Disc Capacitor

The class 2 ceramic disc capacitors usually have much better volumetric efficiency, as the dielectric materials under this class have higher permittivity. However, the capacitors made by the class 2 dielectric materials have considerably lower stability and accuracy. They exhibit a non-linear change in the capacitor based on the given temperature range. So, in short, these capacitors are used in applications where stability and low losses are not of significant importance.

The material that comes under this class is ferroelectric materials which include barium titanate as a base chemical and additives like aluminum silicate, aluminum oxide, and magnesium silicate. Due to their non-linear permittivity, the capacitance varies a lot when the voltage is increased. So here is the table for the class 2 ceramic capacitors based on the EIA standard:

| Low-Temperature Rating

(°C) (°F) |

High Temperature Rating

(°C) (°F) |

Capacitance shift

(%) |

|||

|---|---|---|---|---|---|

| Code | Value | Code | Value | Code | Value |

| X | -55°C (−67 °F) | 4 | +65°C (+149 °F) | P | ±10% |

| Y | -30°C (−22 °F) | 5 | +85°C (+185 °F) | R | ±15% |

| z | +10°C (+50 °F) | 6 | +105°C (+221 °F) | L | ±15% |

| 7 | +125°C (+257 °F) | S | ±22% | ||

| 8 | +150°C (+302 °F) | T | +22/−33% | ||

| 9 | +200°C (+392 °F) | U | +22/−56% | ||

| V | +22/−82% | ||||

Now from the table, it is obvious that if the code is X4P then the lowest temperature will be -55 degrees and the higher temperature will be 65 degrees whereas the capacitance shift will be around 10 percent. So, in other words, the code for class 2 for the standard EIA has three characters: the first one tells the lowest temperature, and the second one tells the highest temperature. Whereas the third and the last character shows the change in the capacitance due to the change in the temperature. Now the codes for the IEC standard are given below in the table:

| Capacitance Change | Temperature Change | |||

|---|---|---|---|---|

| Code | Value at U =0 | Value at U= UN | Code | Value |

| 2B | ±10% | +10/−15% | 1 | −55 − +125 °C |

| 2C | ±20% | +20/−30% | 2 | −55 − + 85°C |

| 2D | +20/−30% | +20/−40% | 3 | −40− + 85°C |

| 2E | +22/−56% | +22/−70% | 4 | −40− + 85°C |

| 2F | +30/−80% | +30/−90% | 5 | (−10 – +70) °C |

| 2R | ±15% | – | 6 | +10 – +85 °C |

| 2X | ±15% | +15/−25% | – | – |

The IEC standard has a code that comprises two characters, the first one tells about the change of the capacitance and the second one tells about the range of the temperature. So, for instance, if the code is 2B1 then it means that the capacitance change is around +10/−15% when the temperature range will be −55 − +125 °C. This way it is quite easy to get the right dielectric material as per the desired values of temperature and capacitance.

Class 3 Ceramic Disc Capacitors

This class of capacitors, like class 2 capacitors, have lower stability and accuracy but have relatively high permittivity and efficiency than the class 2 capacitors. The dielectric material is characterized by a high rate of change of capacitance that is nonlinear. Moreover, this class is no longer standardized by the IEC and EIA standards because it is outdated, and class 2 provides better stability and gives the capacitor a more compact size.

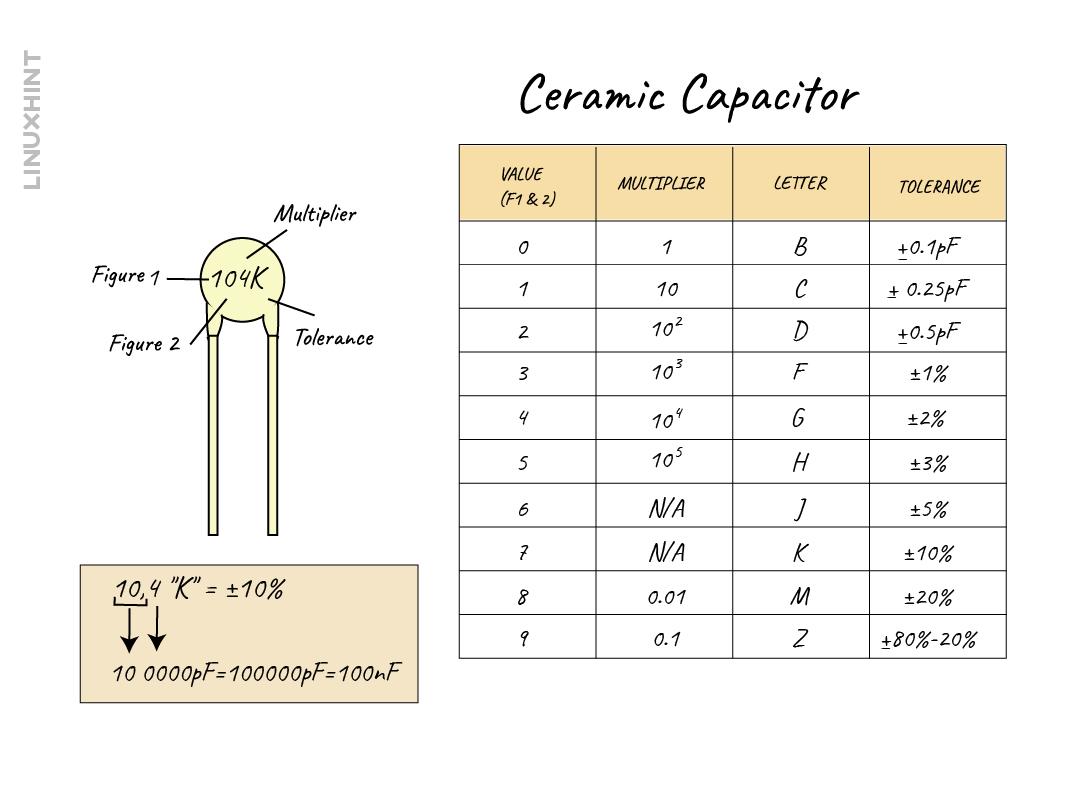

Reading Ceramic Capacitor Values

Ceramic capacitors usually have the values written on their backside in the form of a code. To find out the capacitance of the ceramic capacitor from the code written on the back one needs to understand the code formation. The code is divided into four parts the first two are the figures for the capacitance value and the third one is about the number of zeros after the decimal. The fourth one is usually a letter that tells about the tolerance of the capacitor and to further illustrate here is a capacitor having a code of 104K on its back:

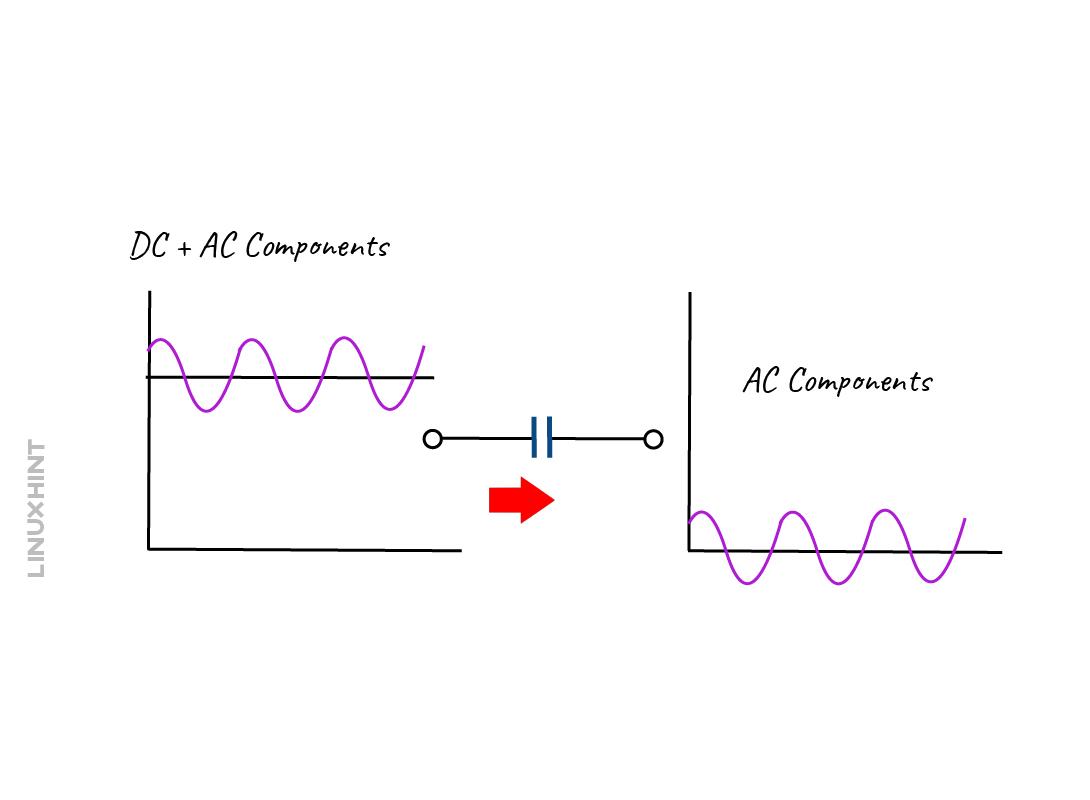

Ceramic Capacitors as Coupling Capacitors

The ceramic disc capacitor can be used as a coupling capacitor, especially in the circuit where only the AC signal is allowed. For instance, if mixed signals are applied, the ceramic capacity will filter the DC components by blocking them and allowing the AC components only. The coupling capacitors are used in audio devices that refrain the DC voltage signal from reaching the load.

Ceramic Capacitors as Decoupling Capacitors

As per the name, the decoupling capacitor serves the purpose of blocking the AC signals, and it is usually connected between the line and the ground of the power supply. Since the ceramic capacitors are non-polarized capacitors, it means that they will resist the flow when the polarity of AC is changed which is experienced in the negative half cycle. This reduces the noise in the signal, which as a result enhances the power supply quality to a greater extent.

Conclusion

Ceramic disc capacitors are disc-shaped capacitors having a ceramic material for insulation between their plates. Further, ceramic capacitors are divided into three classes on the basis of the composition and properties of dielectric material.

If the dielectric is composed of paraelectric materials (class 1) then the capacitors have lower permittivity, high stability, and linear change in the capacitance based on temperature ranges. If the dielectric is composed of ferroelectric material (class 2) then the capacitor exhibits high permittivity, is less stable, and shows non-linear change in the capacitance based on the temperature ranges.